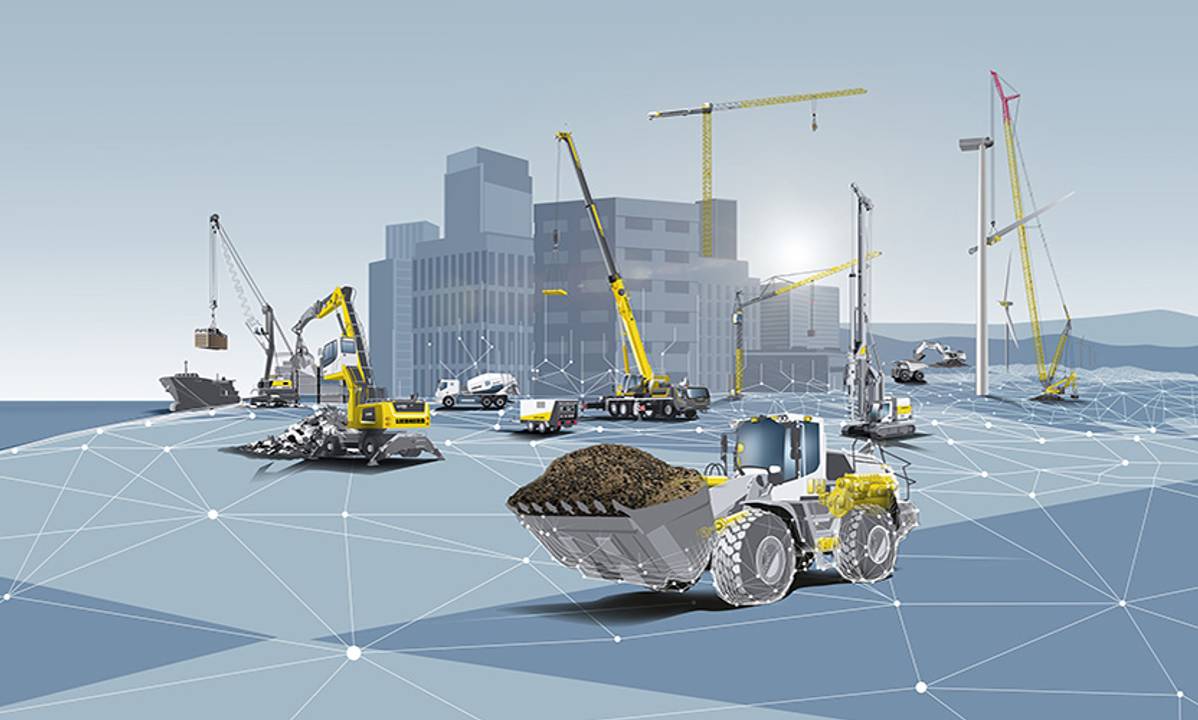

Liebherr sees itself as a major player in the digital transformation of the construction industry. The automation of machines and processes plays a key role here, as it increases the safety, efficiency and cost-effectiveness of construction sites. These are important aspects for the group’s customers in an increasingly challenging competitive environment.

Intelligent control and assistance systems ensure that the machines can react independently to potential obstacles and sources of danger, among other things, and guarantee the precise, efficient implementation of complex processes, such as filling the excavator bucket.

However, there is no such thing as the optimum degree of automation, Liebherr pointed out. Instead, the machine type, area of application and customer requirements define how much automation makes sense at the current time and is desired by the customer. High or even complete automation makes sense for work profiles that are characterised by great monotony.

On urban construction sites with complex, volatile environmental conditions, intelligent assistance systems or partial automation systems that support employees in creative work or for specific solution concepts are an option instead. “We provide differentiated solutions for every application in order to offer our customers maximum benefit,” said Manuel Bös, head of emerging technologies at Liebherr in Bischofshofen. “But they all have one thing in common: they are easy to use and don’t require IT experts.”

Some of these digital technologies were recently showcased to the global media during the Liebherr international construction trade press tour, which was held in Telfs, Austria on 22-23 October 2025.

Liebherr Remote Control

Liebherr Remote Control (LiReCon) enables precise control of construction machines from a safe distance. For example, the system provides access to areas that would be too dangerous for direct manned processing on site. It is also the optimal solution after disasters or for accessing terrain that has become impassable.

With LiReCon, the machine operator swaps the driver’s cab of the construction machine for a teleoperation stand. From there, they use joysticks and screens to remotely control the machine equipped with the LiReCon control architecture and assistance systems via a video remote control system.

Providing fast and stable data transmission, the remote control becomes part of the automated work, as the assistance systems take the strain off the machine operator and visualise all relevant machine data in real time. For example, the blade of a 70-t dozer can be used to precisely grade a constant slope angle hundreds of kilometres away from the work site.

According to Liebherr, LiReCon already fulfils a wide range of customer requirements. It can also be used as a remote maintenance system for offshore cranes. The cross-divisional development makes it possible to remotely control different machines with the LiReCon system and switch between a tower crane, an off-shore machine or earthmoving machines.

LiReCon delivers many advantages, particularly in terms of productivity, as access to the machine is easy. The fact that work is carried out from the operating stand enables quick and safe shift changes, and the operation of different machines increases uptime and optimises the production process. Downtimes are minimised and only affect the machine and not the operator.

“In future, LiReCon will make it possible for certain tasks to come to the operator and for the operator to no longer have to come to the work,” said Florian Falbesoner, group leader for technology and pre-development at the Liebherr plant in Telfs. LiReCon also reduces physical strain, as the machine operator is not exposed to vibrations, noise or dust. Thus the system offers a barrier-free, ergonomic workplace for the future.

Liebherr Autonomous Operations

When it comes to recurring routine tasks such as digging or transporting and installing materials, the autonomous wheel loader from Liebherr can do this independently. But not only that – it recognises obstacles, calculates optimal movement paths and adapts independently to the changing environment. Taking integrated artificial intelligence into account, the machine continuously learns and increases efficiency with every use based on what it has learnt.

The high degree of autonomy results in simple operation. The machine works on the basis of a graphical task definition and makes all the necessary decisions for each work cycle independently. This reduces the need for human monitoring and enables almost round-the-clock operation. The autonomous wheel loader performs its tasks with the utmost precision, and in turn achieves excellent results with lower energy consumption and wear.

At the heart of the autonomous wheel loader is the Liebherr Autonomous Operations system and the Autonomous Job Planner web application. “At Bauma, we already handled several thousand tonnes of bulk goods fully autonomously, which underlines the maturity of the system,” shared Mr Bös. During the test drives for different customer requirements, the focus is on the monotonous feeding of feed hoppers or the stockpiling of material, in quarries, gravel pits and industrial plants.

S1 Vision – new concept in material transport

The S1 Vision has its origins in Liebherr’s mining product segment and was created with the aim of defining the classic mining truck transport concept. The battery-electric, autonomous, single-axle mining truck impresses with its compactness and flexibility.

With a payload of 220 kg up to 131 t, the truck can be used for a wide range of applications – for example in construction, logistics, agriculture or mining. The innovative digital control system makes the S1 Vision particularly future-proof, as it can communicate with other machines in a digital ecosystem.

Liebherr Connect

The construction site of the future is becoming increasingly digital. At Liebherr, its modern connectivity solution, Liebherr Connect, forms the basis for new technologies such as autonomous control, AI-supported maintenance and networked construction sites. Liebherr Connect networks man, machine and environment into a powerful system and therefore creates the basis for autonomous processes. Access to comprehensive machine and process data is only possible through intelligent networking.

In mining operations, Liebherr uses the IoMine platform for networking. It facilitates the transition to integrated operation with a fully networked ecosystem of human-guided and autonomous machine solutions. Liebherr Mining’s expanded technology portfolio increases efficiency, safety and sustainability through real-time data, remote diagnostics and intelligent energy use – reducing costs and optimising fleet management.

Construction site of the future

Liebherr believes that autonomous construction machines will not replace conventional equipment, but rather complement it. Assistance systems support people where they can utilise their strengths to solve problems creatively. If it makes sense, the machine can also be operated remotely from outside the driver’s cab, as with LiReCon, or it can work autonomously in monotonous applications.

Liebherr offers web applications and digital interfaces (API) to analyse the machine data sent and to optimise operations in terms of consumption, idle time, handling capacity and many other aspects. This makes it easier to plan and coordinate processes on the construction site.

Automating recurring tasks speeds up construction projects and significantly reduces costs, stressed Liebherr. At the same time, the use of remote-controlled or autonomous machines in hazardous environments minimises the risk for construction site personnel: a real step forward for safety and productivity on the construction site of the future.